Some machines (smaller washers) have an overflow that is plumbed to drain. So, if water levels are not sensed properly, water valves will stay on but not satisfy the level switches or transducers and the water will flow to sewer through the overflow piping. If that machine does not have an overflow pipe then water will pour out of the shell at the supply injector or whatever opening is lowest on the shell.

If you are having issues with your washer over filling, there are two main places that need to be checked.

- The level hose (that connects the shell to the pressure transducer or pressure switch).

- The pressure transducer or switch.

When water fills the shell of the washer, pressure builds in the level hose. This pressure is sensed by the pressure transducer or switch. Pressure is our key for this solution. Find out where pressure is being lost and we have solved our problem. Here are some possibilities for pressure loss in the hose.

- There is a clog in the hose

- There is a leak in the hose

- There is a leak in the connection either between the shell and the hose or the hose and the pressure transducer / switch

Note:

Never apply air pressure from a compressor or air tank to a pressure transducer. If you need to test a pressure transducer you may apply air pressure using your mouth.

A clogged hose can typically be cleared by disconnecting both ends of the level hose and applying air through the hose using a compressor and air nozzle. Apply air until air flows easily through the hose.

You should suspect a leak in the hose or hose fitting if you see water in the level hose. If not perfectly sealed, water will rise in the hose and obviously the switch or transducer will not detect the level due to the air leak in the hose connection. A leak at the shell may drip but a leak at the hose connection at the switch or transducer will be hard to detect since it is leaking air.

If the pressure transducer has been damaged by over-pressure (which would probably result from a cleaning practice using compressed air) the transducer can be replaced . See notes below.

Both pressure switches and transducers can be damaged by compressed air. So, be careful if using compressed air for cleaning.

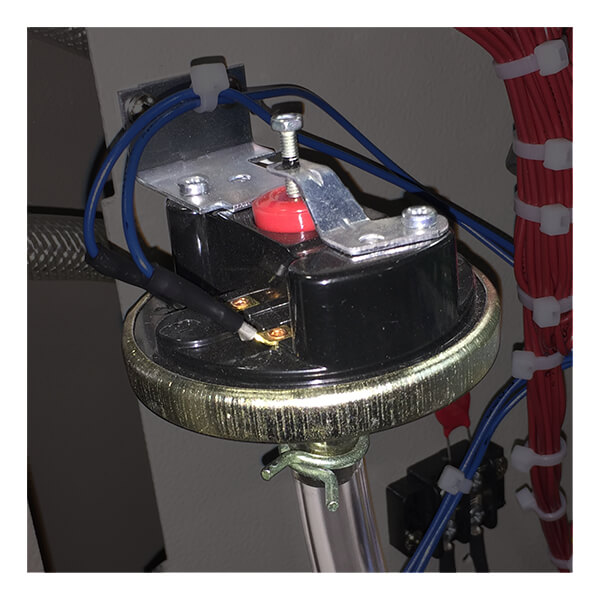

Pressure Switch (E-P OneTouch®, E-P Express®, & Early model E-P Plus®)

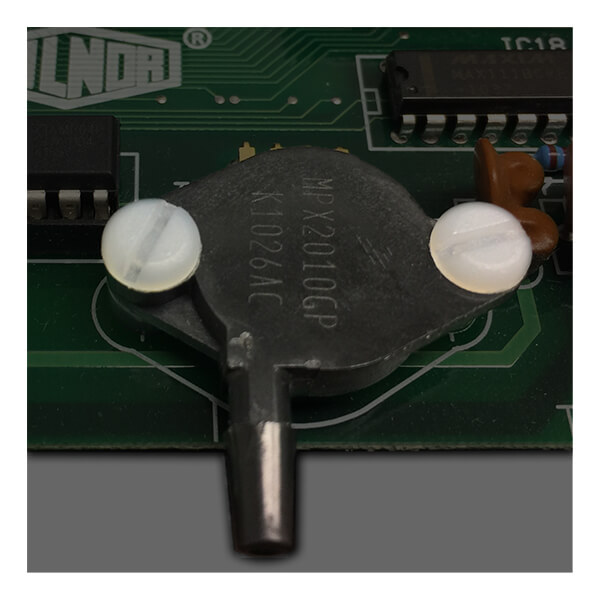

Pressure Transducer (Late E-P Plus®)

The pressure transducer for the

08BH18EPDT, 08BH188AT, 08BH188BXT -

08CIF2010. This has 4 pins connected to the board.

This can be replaced by a competent repair technician using a soldering iron and associated removal tools.

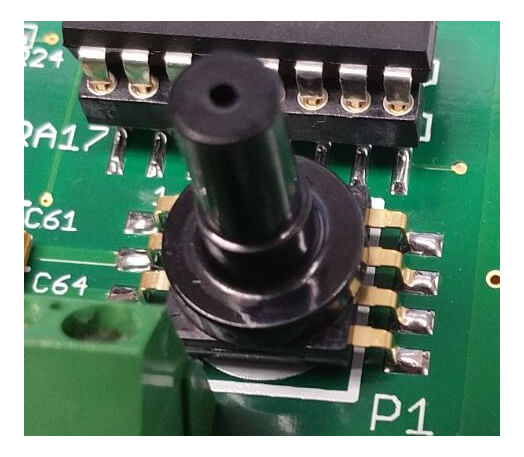

Miltouch™ - Single board IO transducer (Board number 08BHF120AT)

The pressure transducer for the

08BHF120AT is

08CIF5010. This has 8 pins connected to the board.

This can be replaced by a competent repair technician using a soldering iron and associated removal tools.